- Bienvenue sur notre site

- WhatsApp: +86 187 0363 7156

- Email:[email protected]

ball mill technique

- Accueil

- >

- ball mill technique

ball mill technique

ball mill technique :

Ball Mill - an overview ScienceDirect Topics

For instance, a ball mill, which is a powder-processing technique involving deformation, cold welding, fracturing, and rewelding of powder particles, is used for mechanical alloying.

Read More

Ball milling as a mechanochemical technology for fabrication

2020.9.1 Different types of ball milling and its working principles: (a) planetary ball milling, (b) tumbler ball milling, (c) attrition ball milling, and (d) vibration ball milling (where

Read More

Ball milling – A green and sustainable technique for the preparation

2022.1.1 Ball milling is a mechanical technique used to grind powders into fine particles [1]. Generally, a ball mill consists of a hollow cylindrical vessel that rotates

Read More

Ball milling as an important pretreatment technique in

2021.8.12 Both attrition and planetary ball mills were effective to reduce particle size, minimize waste generation, and loss of biomass, as compared to tumbling ball mill .

Read More

Ball Milling in Organic Synthesis: Solutions and Challanges

2011.3.2 For most applications in organic synthesis, including catalysis, ceramic materials (e.g. ZrO 2) are the best choice. They are chemically inert and the material

Read More

Full article: Ball milling: a simple and efficient method for ...

2021.4.12 A simple and efficient technique for quantitative solvent-free synthesis of Ni (II) and Co (II) complexes by using ball milling as a green strategy is studied. The

Read More

Ball milling in organic synthesis: solutions and challenges

The central aim is to motivate researchers to take notice of ball mills as chemical reactors, implementing this technique in everyday laboratory use and thus, pave the ground for

Read More

Facile, fast, and green preparation of high-purity and

2023.1.12 In the ball mill technique, different parameters, such as milling rotation speed (6–240 rpm), powder-to-ball ratio (1:5, 1:10, 1:20 kg), milling time (3–12 h), air

Read More

Catalysts Free Full-Text Solvent-Free Biginelli Reactions

A sustainable, green one-pot process for the synthesis of dihydropyrimidinones (DHPMs) derivatives by a three-component reaction of β-ketoester derivatives, aldehyde and urea or thiourea over the alkali-treated H-ZSM-5 zeolite under ball-milling was developed. Isolation of the product with ethyl acetate shadowed by vanishing of solvent was applied. The

Read More

Applied Sciences Free Full-Text Recent

2022.9.16 This review is focused on the topical developments in the synthesis of nanocomposites using the simplest top-down approach, mechanochemical milling, and the related aspects of the interfacial

Read More

Ball milling in organic synthesis: solutions and challenges

During the last decade numerous protocols have been published using the method of ball milling for synthesis all over the field of organic chemistry. However, compared to other methods leaving their marks on the road to sustainable synthesis (e.g. microwave, ultrasound, ionic liquids) chemistry in ball mills is rather underrepresented in the

Read More

Ball milling: a green technology for the preparation and ...

this green, sustainable technique to facilitate the identi cation of areas of future development. The ball mill Ball milling is a mechanical technique widely used to grind powders into ne particles and blend materials.18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world.

Read More

Model Study of Mechanicochemical Degradation in a Planetary Ball Mill

2023.1.11 The process of ball milling and the materials that compose planetary ball mills are highly complex, and the existing research on the change in ball-milling energy is not mature. The theoretical model of a ball mill was established for the first time to simulate the motion, collision process, energy transfer, and temperature change of small balls during

Read More

Ball Mill - an overview ScienceDirect Topics

For instance, a ball mill, which is a powder-processing technique involving deformation, cold welding, fracturing, and rewelding of powder particles, is used for mechanical alloying. ... Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig. 2.12). Such a ball ...

Read More

Particle morphology control of metal powder with

2021.12.1 Mechanical alloying (MA) is a solid-state powder processing technique that involves repeated cold welding, fracturing, and rewelding of powder particles in a high-energy ball mill [3], MA widely used technique in synthesizing nanocrystalline materials and also. it has been used to prevent the reinforcement clusters or agglomerates on the

Read More

Molecules Free Full-Text Ball Milling Promoted N ... - MDPI

2018.6.4 In the last years, numerous protocols have been published using ball milling for organic synthesis. Compared to other methods such as microwave or ultrasound irradiation and ionic liquids, ball mill chemistry is an economical, and ecofriendly method in organic synthesis that is rather underrepresented in the knowledge of organic chemists.

Read More

Recent advances in the treatment of contaminated soils by ball

2022.3.15 Heavy metals, metalloids, and nuclides accumulated in soils through the food chain cause many human health problems (Bian et al., 2013; Bolan et al., 2014). It is necessary to search for a remediation technique that uses few chemical reagents and simple operating conditions. Ball mill is an excellent immobilization technique.

Read More

Ball-milling - ResearchGate

2023.12.11 Ball milling is an economic and facile technique to produce nanosized materials. It is a top-down ... Ball mill is crucial to numerous industries as an equipment for producing extremely crushed ...

Read More

Ball-milling: A sustainable and green approach for starch

2023.5.15 Ball-milling is a low-cost and green technology that offers mechanical actions (shear, friction, collision, and impact) to modify and reduce starch to nanoscale size. It is one of the physical modification techniques used to reduce the relative crystallinity and improve the digestibility of starch to their better utility.

Read More

A review on mechanical activation and mechanical

2019.8.1 This method allows production of homogeneous materials starting from blended elemental powder mixtures produce a nickel-based superalloy. Mechanical alloying (MA) is a solid-state powder processing technique that involves repeated cold welding, fracturing, and rewelding of powder particles in a high-energy ball mill.

Read More

Ball milling as a synthesis method - Aalto

2022.4.4 Ball mills can be classified into high-energy ball mills and low-energy ball mills by their rotation speed. Selection of certain ball mill depends on used technique; MA, MM or MD. However, some ball mills can be utilized for all three of these techniques. Table 2 presents the most common ball mills and their energy types. [1, p.26] [4] Table 2.

Read More

Mechanochemical techniques for the activation and use of

2022.7.21 Activating raw, zero-valent metals is an essential capability for chemical processes, which include synthesis and catalysis. In recent years there has been the discovery and growing intensity in ...

Read More

Mechanical Milling: A Superior Nanotechnological Tool for Fabrication ...

2021.9.24 Mechanical alloying (MA) is a typical solid-state process that occurs at room temperature between powders of diffusion couples utilizing various types of ball mills. Ball milling has evolved over the last five decades from a standard technique in mineral dressing and powder metallurgy, where it was primarily used for particle size reduction

Read More

A Review of Alternative Procedures to the Bond Ball Mill

2021.7.12 Over the years, alternative procedures to the Bond grindability test have been proposed aiming to avoid the need for the standard mill or to reduce and simplify the grinding procedure. Some of them use the standard mill, while others are based on a non-standard mill or computation techniques. Therefore, papers targeting to propose a better

Read More

Nanomaterials Free Full-Text Mechanical Milling: A

2021.9.24 Mechanical alloying (MA) is a typical solid-state process that occurs at room temperature between powders of diffusion couples utilizing various types of ball mills. Ball milling has evolved over the last five decades from a standard technique in mineral dressing and powder metallurgy, where it was primarily used for particle size reduction

Read More

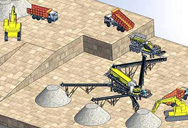

Practical modern techniques for the design of comminution

A number of modern techniques suitable for the design of crushing and grinding circuits are described. The methods are based on extensive use of mathematical models of crushers, mills and classifiers and are seen as alternatives to conventional comminution design methods based on Work Indexcalculations. The parameters used in comminution models ...

Read More

Mixing methods for solid state electrodes: Techniques,

2023.5.15 The type of mill decides the kinetic energy transferred to the powders and therefore the specific purpose of the technique. Vibratory ball mills (Fig. 4 a) are constituted by a narrow cylindric tank where the powders and balls are subjected to quick oscillations of small amplitude to obtain high milling forces to decrease the size of the ...

Read More

Modelling the performance of industrial ball mills using

1987.7.1 This ball mill modelling technique is illustrated using a case study on the design of a ball milling circuit for a particular grinding requirement and another case study on modelling the performance of an industrial ball milling circuit. INTRODUCTION Comminution is an energy-intensive process and consumes approximately 3% of the electricity ...

Read More

Investigation on structural and adsorptive features of

2023.4.15 The synthesis of composites, which is a metal oxide-clay combination, has been successfully carried out with the cheap, easy and solvent-free ball-mill technique. Different structures were formed during the grinding of the composites using a ball-mill, these are Ba(OH) 2 H 2 O, Al 2 O 3 H 2 O, HAlSi 4 O 10, SiO 2 and BaSiOH 2 O.

Read More

Energies Free Full-Text Energy-Efficient Advanced Ultrafine

2023.7.10 The present literature review explores the energy-efficient ultrafine grinding of particles using stirred mills. The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills. It also discusses the factors, including the design, operating parameters, and feed material

Read More

Wet ball milling of niobium by using ethanol, determination

2021.11.17 This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb). Dried nanocrystal Nb powders, of high purity, with particle sizes ...

Read More

Mechanistic modeling and simulation of grinding iron

2021.11.1 An industrial ball mill was then laser scanned and surveyed, including measurements of residence time distribution. ... Other examples of application of the technique to industrial mills are provided by Austin et al. [10] and Kown et al. [11]. However, in spite of the success of the size-mass balance models in design and optimization of ball ...

Read More

A new approach for remediation of As-contaminated soil: ball mill-based ...

2015.12.15 In this study, a physical ball mill process instead of chemical extraction using toxic chemical agents was applied to remove arsenic (As) from contaminated soil. A statistical analysis was carried out to establish the optimal conditions for ball mill processing. As a result of the statistical analysis, approximately 70 % of As was removed from the

Read More

Ball milling as an important pretreatment technique in

2021.8.12 The load exerted by grinding balls on lignocellulosic biomass in a vibratory ball mill is significantly larger than the other mill types, resulting in the highest enzymatic hydrolysis yield. The glucose yields achieved were 95.2, 75.2, 61.0, and 52.8%, for vibratory ball mill, tumbler ball mill, jet mill, and centrifugal mill, respectively ...

Read More

Producing Metal Powder from Machining Chips Using Ball

2023.6.27 2.3.1. Impact of Different Ball Mill Jars on Mechanical Properties . Ball milling is a widely used technique for the preparation and modification of various materials. The capabilities of the ball mill jars used throughout the milling process significantly impact the mechanical characteristics of the finished goods.

Read More

Surface modification of silica powder by mild ball milling

2022.11.5 Amorphous silica powder (SO-C1, Admatechs, Aichi, Japan) was used to prepare modified silica. The average diameter was 230 nm and a specific surface area of 16.2 m 2 /g measured using the Brunauer-Emmett-Teller method. Twenty grams of silica powder and 250 g of zirconia balls with a diameter of 5 mm were placed in a 250 ml

Read More

Ball Mill: Operating principles, components, Uses,

2022.11.30 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

Read More

- concasseurs à mâchoires bentonite

- utilisé utilisé de concassage de pierre à vendre en Malaisie

- briquette de charbon en poudre liant les fabricants

- le concassage de pierres equipements zenith

- un rapport dune à un concasseur

- efficiency of jaw crushers

- la construction dun broyeur à billes

- moulin de bague doccasion à vendre

- construction des équipements de concassage afrique du sud

- concasseur à mâchoires malaisien

- hpc oro trituradoras de rodillos

- concasseur à mâchoires identification

- de l europe fonction de l usine de concasseur

- installation mobile de concassage Indonésie vendre le charbon russe

- Broyeur De Pierres Prodak