- Bienvenue sur notre site

- WhatsApp: +86 187 0363 7156

- Email:[email protected]

extracting iron from its ore flow chart

- Accueil

- >

- extracting iron from its ore flow chart

extracting iron from its ore flow chart

extracting iron from its ore flow chart :

The six main steps of iron ore processing - Multotec

1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to

Read More

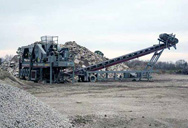

Simplified flow chart showing typical iron ore

... activities involved in mining and processing iron ore on site are shown in the flow chart in Figure 1. Ore processing ranges from simple crushing and screening methods to more...

Read More

Iron processing Definition, History, Steps, Uses,

Dec. 18, 2023, 5:33 PM ET (AP) Storied US Steel to be acquired for more than $14 billion by Nippon Steel iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned.

Read More

Recent Trends in the Technologies of the Direct Reduction

Schematics of an experiment flow chart of direct reduction of iron ore/oxide. In this process, iron is extracted from its ore at a temperature below the melting points of the materials

Read More

Iron Ore Characterization Techniques in Mineral Processing

2023.4.27 While iron is a pivotal metal that is exploited commercially, its extraction from ores, subsequent processing and purification follows a series of steps, and material

Read More

Iron Ore production in the Pilbara - Rio Tinto

2023.6.2 Iron Ore production in the Pilbara. Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following

Read More

Iron Ore Processing, General SpringerLink

2022.10.20 Table 1 Common iron ore minerals. Full size table. The iron ore processing industry produces usable concentrations of iron-bearing material by removing

Read More

The Extraction of Iron - Chemistry LibreTexts

This page looks at the use of the Blast Furnace in the extraction of iron from iron ore, and the conversion of the raw iron from the furnace into various kinds of steel. Contributors

Read More

Extraction of Iron: Meaning, Purification,

2023.5.14 The most commonly used iron ores are Hematite, Fe2O3, and magnetite \ (Fe_ 3 O_ 4\). The process of extraction of iron and their separation is followed by three major steps: Concentration of Ore.

Read More

Iron- and Steel-Making Process SpringerLink

2020.6.10 Iron is extracted in the form of metallic iron (Fe) by reducing the oxide ores with a reducing agent. The principal agents commonly employed to serve this reduction process are the naturally occurring forms of carbon such as coke, charcoal and coal. In order to extract the iron, Fe (55–60%)-rich ore is usually used.

Read More

(PDF) The extraction of tin (Sn) from primary tin ore deposits

2021.11.1 This research aims to observe the extraction of tin from primary deposits (oxide and skarn ores) using HCl wet chlorination, observed at different temperature (60 – 90°C), HCl concentrations ...

Read More

Recent Trends in the Technologies of the Direct Reduction

Schematics of an experiment flow chart of direct reduction of iron ore/oxide. In this process, iron is extracted from its ore at a temperature below the melting points of the materials involved. ... Li K, Wen N, Zhu M, Zheng M, Yuan L. Iron extraction from Oolitic iron ore by a deep reduction process. Journal of Iron and Steel Research ...

Read More

Iron Ore Processing, General SpringerLink

2022.10.20 Iron ore handling, which may account for 20–50% of the total delivered cost of raw materials, covers the processes of transportation, storage, feeding, and washing of the ore en route to or during its various stages of treatment in the mill.. Since the physical state of iron ores in situ may range from friable, or even sandy materials, to monolithic

Read More

Extraction of Iron from its ores, Iron dressing, Reduction production ...

2018.10.23 S + O 2 → SO 2. 4 P + 5 O 2 → 2 P 2 O 5. Roasting is the process of heating iron ore strongly in dry air for drying the ore and expelling humidity, It is used to increase the percentage of iron in the ore and for the oxidation of some impurities such as sulphur and phosphorus.. Roasting of iron is very important in the ore dressing process

Read More

How to extract iron ore flow chart? - LinkedIn

2023.1.6 Here is a basic flow chart outlining the steps involved in the production of iron from iron ore: Mining: Iron ore is typically mined in large, open pits using heavy machinery. Crushing: The ...

Read More

en/flow diagram steps of iron to iron ore.md at main

Contribute to dinglei2022/en development by creating an account on GitHub.

Read More

Extraction of Aluminium (Aluminium Ore) - Hall-Heroults

The Hall-Heroult process is widely used in the extraction of aluminium. In Hall-Heroults process, pure Al 2 O 3 is mixed with CaF 2 or Na 3 AlF 6. This results in lowering the melting point of the mixture and increases its ability to conduct electricity. A steel vessel with a lining of carbon and graphite rods is used.

Read More

Lesson Explainer: Extracting Iron Nagwa

Lesson Explainer: Extracting Iron. In this explainer, we will learn how to describe the extraction of iron from its ore in the blast furnace. Extraction of iron is arguably one of the most important industrial processes on Earth. Iron is used to make steel, which is incredibly important for constructing transport vehicles and large buildings.

Read More

extracting iron from its ore flow chart

the process of extracting iron ore in the form of a flow chart iron ore mining extraction staff process flow chart Iron processing Britannica Iron processing, Home Products

Read More

Lesson Video: Extracting Iron Nagwa

Video Transcript. In this video, we will look at the extraction of iron from its ore in the blast furnace. We’ll look at the chemicals used in a blast furnace and the temperatures involved. Iron is an abundant metal, which is relatively cheap to produce. Ores containing a high proportion of iron can be found throughout the world.

Read More

Iron Ore Characterization Techniques in Mineral Processing

2023.4.27 While iron is a pivotal metal that is exploited commercially, its extraction from ores, subsequent processing and purification follows a series of steps, and material characterization in terms of physical, chemical and mineralogical features and behavior is imperative at each stage. Some characterization tests rely solely on physical

Read More

Hydrometallurgical Processing of Manganese

2011.1.1 After precipitation, the extraction of Zn from the Fe, Al and Cr free leach liquor was carried out with 0.1 mol/L TOPS-99 followed by Mn extraction with 0.04 mol/L NaTOPS-99. The yields of Zn and ...

Read More

Iron processing Definition, History, Steps, Uses, Facts

2023.12.18 iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties.

Read More

en/extraction of zinc from its ore on flow chart.md at main ...

Contribute to dinglei2022/en development by creating an account on GitHub.

Read More

extracting iron from its ore flow chart

the process of extracting iron ore in the form of a flow chart iron ore mining extraction staff process flow chart Iron processing Britannica Iron processing, Home Products

Read More

en/flow chart images of extraction of ferrous metals.md at

Contribute to dinglei2022/en development by creating an account on GitHub.

Read More

Iron Ore Processing, General - Springer

2022.10.19 The iron ore processing industry produces usable concentrations of iron-bearing material by removing nonferrous rock (gangue) from low-grade ore. In the United States, predominant iron ore is taconite which is a hard, banded, low-grade ore. Ninety-nine percent of the crude iron ore produced in the United States is taconite.

Read More

23.2: Pyrometallurgy - Chemistry LibreTexts

Pyrometallurgy in the Extraction of Iron. Pyrometallurgy is also used in the iron and steel industries. The overall reaction for the production of iron in a blast furnace is as follows (via \(\ref{2.1}\)): ... The furnace is charged with alternating layers of iron ore (largely Fe 2 O 3) and a mixture of coke (C) and limestone (CaCO 3). Blasting ...

Read More

The Extraction of Iron - Chemistry LibreTexts

This page looks at the use of the Blast Furnace in the extraction of iron from iron ore, and the conversion of the raw iron from the furnace into various kinds of steel. Contributors and Attributions. Jim Clark (Chemguide.co.uk) Prof. Robert J. Lancashire (The Department of Chemistry, University of the West Indies)

Read More

How to Extract Iron from Hematite: Methods and

2023.2.15 Hematite, also spelled haematite, is a weakly magnetic iron ore with better floatability than magnetite and wide distribution.It is one of the most important raw materials for the extraction of iron. Its

Read More

extracting iron from its ore flow chart

the process of extracting iron ore in the form of a flow chart iron ore mining extraction staff process flow chart Iron processing Britannica Iron processing, Home Products

Read More

The Metallurgy Process Australian General Engineering

2023.2.9 The Metallurgy technique is a lengthy and intricate process. Ore is first extracted from open pits or underground mines using a variety of methods, including tunnelling and hand-digging. The next step in processing mined ore is crushing it into smaller bits. Metals must undergo additional processing after mining and crushing to be used in

Read More

The extraction of metals CPD RSC Education

2019.12.11 Students can perform reduction experiments themselves such as reducing iron oxide to iron. A favourite class practical lesson is extraction of iron on a match head (rsc.li/2P4VEIT). Begin by showing a sample of the iron ore haematite. Discuss sources of iron ore and mines such as the former Florence iron mine in Egremont,

Read More

Metals Extraction from Sulfide Ores with Microorganisms:

2019.1.2 Bioleaching is the metal-extracting practice from sulfides and/or iron-containing ores by means of microorganisms. It is a specified biohydrometallurgical approach in which either the metabolic activities or microbe’s products are used to convert insoluble compounds into soluble form, which can then be recovered later [].Biological

Read More

2022/sbm diagram of how iron ore is mined.md at main

Contribute to naicha22/2022 development by creating an account on GitHub.

Read More

Extraction Of Iron PPT - SlideShare

2009.5.22 6. Occurrence of Iron Iron is very reactive and is found in nature in form of its oxides, carbonates and sulphates. The main ores are: i) Haematite (Fe2O3) ii) Magnetite (Fe3O4) iii) Iron Pyrites (FeS2) o The main iron ore is Haematite (iron (III) oxide - Fe2O3). o The iron ore contains impurities, mainly silica (silicon dioxide). o Since iron is below

Read More

Extraction of Aluminium - Step By Step Guide

2022.12.19 Extraction. The first step in aluminium processing involves extracting bauxite ore from the ground. Bauxite is a mineral composed mostly of aluminum hydroxide and other compounds like silica, iron oxide, titanium dioxide, and kaolinite. The bauxite ore must be extracted from deep within the earth using heavy machinery such as bulldozers

Read More

Metal Ore Extraction and Processing - Springer

2017.8.23 In modern metal ore extraction, the most common technique is open-pit mining. In much the same manner as open-pit coal extraction, soils and vegetation are first ... the recycling value of scrap steel and has decreased iron extraction pressures. Text Box 10.1 American Scrap Metal Feeds China’s Growing Steel Industry

Read More

- broyeur de pierres crusherprice

- Chine Top Ten entreprise de concassage de pierres

- la exploitation de la wollastonite concasseur

- fournisseur de concasseur percussion calcaire au nigeria

- 120 tph usine pierre de concassage

- Comment fonctionne billes de broyage des médias

- l'équipement de terrassement pour la location freestate

- pierre de quartz machines de concassage

- cara bongkar mesin fraisage bridgeport

- l équipement pour l usine de ciment

- recyclage des déchets machine de vidéo

- pfiefer meulage balle producteur de la machine en allemagne

- dimension de minerai de calcaire flux de traitement de la pierre

- moulins pot de laminoir

- manfactures machine broyeur en Nouvelle Caldonia