- Bienvenue sur notre site

- WhatsApp: +86 187 0363 7156

- Email:[email protected]

dry magnetic mining method

- Accueil

- >

- dry magnetic mining method

dry magnetic mining method

dry magnetic mining method :

Processes Free Full-Text Beneficiation of

2022.10.27 Introduction. Iron-containing ore beneficiation includes several stages. For example: crushing to −30 mm size class and rough magnetic separation, further crushing of the recovered magnetic product

Read More

Dry beneficiation of iron ore - Mineral Processing

Dry beneficiation of iron ore Falling prices for iron ore with lower quality than 60 % Fe have led increasingly to the design of iron ore beneficiation lines. General problems of water

Read More

Minerals Free Full-Text Influence of Mineralogy on the Dry Magnetic ...

2021.1.31 Magnetic separation is one of the most widely used processes for the upgradation of manganese ore. Furthermore, dry-based magnetic separation methods

Read More

Full article: Demonstration of dry magnetic separation to

2023.6.17 Dry Induced Roll Magnetic Separation (IRMS) is one potential method for upgrading the Mn content and Mn:Fe ratio of ferromanganese ore fines, as the more

Read More

How fines dry magnetic separation could solve

2021.3.19 World Mining Frontiers writer Andrea Valentino talks to Sunil Tripathy, an expert in mineral extraction at the University of Lorraine, about how new fines dry magnetic separation (FDMS) could finally put

Read More

Dry Mineral Processing SpringerLink

2022.2.28 This book introduces and explains all existing dry processing methods, drawing from larges studies about these techniques in both the academia and industrial sectors. Potentially, water insufficiency

Read More

Magnetic separation studies for a low grade siliceous iron ore sample

2013.1.1 Many mineral processing industries want to purify the magnetic minerals from the non-magnetic portions by using the dry magnetic separation techniques. The

Read More

For dry and wet processing Low Intensity Magnetic

2022.8.10 Gravity separation (jigging) is common for hematite, while dry magnetic (dry LIMS) separation is the preferred method for magnetite.

Read More

Dry Magnetic Separation of Iron Ore of the Bakchar Deposit

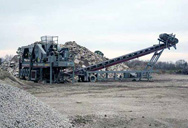

2015.1.1 In mining industry the technology of preliminary minerals concentration with self-propelled crushing-concentrating plants should be applied9. Nevertheless, some authors10-12 propose the flotation concentration of iron ore. However, this method is prolonged and more technically difficult as it requires careful drying of iron concentrates

Read More

For dry and wet processing Low Intensity Magnetic

2022.8.10 (jigging) is common for hematite, while dry magnetic (dry LIMS) separation is the preferred method for magnetite. If the ore’s liberation characteristics require further ... magnetite run of mine due to the mining method used. By increasing the wet process iron feed grade by only a few percent by pre-concentration, significant gain can be

Read More

Minerals Free Full-Text Separation Analysis of New Magnetic

2022.6.1 To achieve the utilization of fine ilmenite (especially −0.075 mm) produced in the titanium-magnetite processing plant in Panzhihua, a radial turbulent outer-cylinder magnetic separator (RTOCMS), was developed in this study. After optimizing the conditions of rotation speed and water flow, an RTOCMS concentrate with TiO2 grade of 22.84%

Read More

Physical separation of iron ore: magnetic separation

2022.1.1 The first SLon-2500 vertical ring-pulsating high gradient magnetic separator was designed and built up in 2006. It was installed at the tails dam of Hai Nan Iron Mining Company to recover iron ...

Read More

Minerals Free Full-Text Influence of Mineralogy on the Dry Magnetic ...

2021.1.31 Furthermore, dry-based magnetic separation methods are gaining importance due to advantages such as water saving, and avoiding the tailing dam/dewatering step [15,16,17,18,19,20]. The magnetic susceptibilities of the major manganese minerals and associated gangue bearing minerals are tabulated in Table 1 [

Read More

Evaluation of mining and mineral processing methods’

2020.12.1 The ore is exploited by open pit mining method and processed at mine site using magnetic and gravitational methods (Jordan et al. 2012; Dawd 2016). According to EMDSC, annual production of the concentrate is fluctuating between 150 and 200 tons with 40–50% Ta 2 O 5 and 15–20% Nb 2 O 5 (internal report of EMDSC 2010).

Read More

Evaluation of mining and mineral processing methods’

2020.12.1 The ore is exploited by open pit mining method and processed at mine site using magnetic and gravitational methods (Jordan et al. 2012; Dawd 2016). According to EMDSC, annual production of the concentrate is fluctuating between 150 and 200 tons with 40–50% Ta 2 O 5 and 15–20% Nb 2 O 5 (internal report of EMDSC 2010).

Read More

ENRICHMENT OF LOW GRADE MAGNETITE ORE BY MAGNETIC

2021.1.8 The major concentration methods that may be applied to upgrade lower-grade lump iron ores include magnetic separation, wet and dry heavy media separation, and air-pulsed jigging.

Read More

6 Magnetic Separation - Springer

2017.8.25 Plant Design, Society of Mining Engineers AIME, New York, 1980, p. 475. Reproduced with the permission of the Society for Mining, Metallurgy, and Exploration. separator consists of a stationary magnet inside the head pulley of a belt conveyor, with the magnet positioned so that magnetic material is held to the belt and drops

Read More

Processing the ores of rare-earth elements MRS Bulletin

2022.3.21 Rare-earth elements (REEs) are required for use in modern high-tech applications and demand has increased significantly over the last decade. 1 However, processing of REE ores poses potential hazards to human health and the environment due to challenges in the management of thorium (Th) and uranium (U) in waste products. 2 If

Read More

Magnetic separation studies for a low grade siliceous iron ore sample

2013.1.1 The −10 mm crushed bulk sample was subjected to size classification using dry sieving method up to −0.500 mm using 6, 3, 2, 1, 0.850, 0.500 mm screens and then wet sieving method using 0.300, 0.210, 0.100 mm screens.All the size fractions were analyzed for Fe content. The weight (%) and Fe (%) of different size fractions are given in Table 2.

Read More

Magnetic Separation SpringerLink

2022.2.28 2.1 Introduction. The differences in magnetic susceptibility can be utilized to separate a valuable mineral from its gangue through the magnetic separation method. Similar to other materials, minerals are generally classified into three main categories, namely diamagnetic, paramagnetic, and ferromagnetic.

Read More

Chapter 2 Magnetic Separation - Springer

2023.3.21 2.4 High-Gradient Magnetic Separator (HGMS) As its name implies, a high gradient magnetic separator employs magnetic field charges to separate magnetic materials. Marston and Kolm introduced this method at the Massachusetts Institute of Technology in the late 1960s and early 1970s.

Read More

Progress in developments of dry coal beneficiation

2014.8.21 Luo et al. studied the effect of a secondary gas-distribution layer on the fluidization characteristics of an ADMFB for dry coal beneficiation and the experimental results show that the secondary layer with an optimal depth of 30 mm can significantly reduce the variance in both the bed pressure drop and the bed density, leading to an

Read More

Zircon Concentrate Enrichment by Dry Magnetic Separation

2023.3.13 The possibility of enrichment and radioactivity reduction of zirconium concentrate obtained at the Obukhovsky mining and processing plant, located in the North Kazakhstan region, was investigated. The zircon concentrate was enriched and deactivated by dry magnetic separation and centrifugal air separation. The elements distribution over

Read More

Assessing the performance of a novel pneumatic magnetic separator for ...

2020.9.1 Dwari et al. (2013) used a combination of dry and wet magnetic separation methods to upgrade a low-grade siliceous iron ore with magnetite, hematite, and goethite as major iron minerals. The study showed that for particles finer than 200 µm, the separation methods produced a magnetic concentrate with 67% iron and iron recovery of 90%.

Read More

Beneficiation of lunar soils: Case studies in magnetics Mining ...

1992.8.1 Reported are weight, particle size, gross chemistry and magnetism measurements for lithic, mineral and fused soil components separated from five lunar soils using dry, open-gradient, magnetic separation. Pure diamagnetic anorthite, a feedstock for the electrochemical separation of oxygen and metals, has been separated from

Read More

Magnetic Separation Process SpringerLink

2023.6.22 Magnetic Separation Process. Magnetic separation process is a combination and procedure for separating magnetic materials from non-magnetic materials by utilizing magnetic separation. In view of the difference in physical and chemical properties of the materials to be processed, the crystal sizes of the magnetic materials, the

Read More

Physical Concentration of Heavy Minerals: A Brief Review on

2023.12.12 Albeit somewhat environmental challenges and eco-unfriendliness are often caused by the dry magnetic concentration method, it is, however, established as a simple and cost-effective technique and very efficient in mineral processing/beneficiation of HMs, as these minerals are usually composed of both diamagnetic and paramagnetic as

Read More

Magnetic separation studies for a low grade siliceous

2013.1.31 The best concentrate with 92,47% Fe2O3 grade and 69,91% recovery yield could have been obtained from the ore containing 62,94% Fe2O3 by high intensity wet magnetic separation method at 6000 Gauss ...

Read More

Minerals Free Full-Text A Novel Pneumatic Planar Magnetic

2020.8.27 In our previous studies, we investigated the performance of a novel pneumatic planar magnetic separator (PMS) for the dry beneficiation of a selected magnetite ore. In the present study, we have extended the studies on the PMS with the focus on investigating how various PMS processing flowsheet configurations influence its

Read More

Physical separation of iron ore: magnetic separation

2022.1.1 Magnetic separation is the most efficient separation method of these technologies. Modern magnetic separators are capable of processing up to 500 t ore/h per unit at a very low operating cost ... The run-of-mine ore is mainly composed of specularite and quartz. The ore is first ground down to about 85% −75 micron particle size using ball ...

Read More

ADVANCES IN MAGNETIC SEPARATION OF ORES - 911

2016.12.4 I-Dr!y magnetic processing of nepheline syenite. netic material removed is quite small, and dry sep- aration is the general rule. Magnetic separation is also important in process- ing phosphate, titanium, chrome, manganese, tung- sten, molybdenum, nickel, niobium, and tantalum ores. Pioneer Work on Dry Separation: It is interesting

Read More

Influence of Separation Angle on the Dry Pneumatic Magnetic

2022.8.18 A laboratory dry pneumatic flat magnetic separator (DPFMS) applying airflow in the opposite direction of magnetic force was designed and manufactured. An artificial mixture of magnetite and quartz with the size range of −0.15 + 0.074 mm was used to test and investigate the separation performance and mechanism.

Read More

(PDF) Dry Permanent Magnetic Separator: Present Status

2022.9.30 Abstract and Figures. Dry permanent magnetic separators have been widely used in the mineral and coal processing industries due to their simple operation and high separation efficiency. These ...

Read More

Minerals Free Full-Text Analysis of the Effect of Dry Magnetic ...

2021.7.22 The paper considers the results of the application of dry magnetic separation on samples of ferruginous quartzites of the Kostomuksha ore field, represented by refractory ore, free-milling ore, and their mixture. The assessment of the influence of the ore texture on the technological parameters of dry magnetic separation indicates their

Read More

Production of trona concentrates using high-intensity dry magnetic ...

2011.5.1 Soda ash, an essential raw material for major industries, such as the glass, chemicals, soap and detergents, pulp and paper, mining and water treatment industries, is traditionally produced by chemical and thermal treatment of trona ore. The treatment processes for trona ore are not only chemically expensive but also energy intensive.

Read More

Investigation of the magnetic separation performance of

2022.3.1 Lowintensity magnetic separators, which comprise one of the most widely employed magnetic separation equipment, in both dry and wet forms, concentrate relatively large and highly magnetic ...

Read More

- des broyeurs à boulets novembre

- deuxième main pierres de concassage en Tunisie

- production de minerai de cobalt de zambie 2010

- molino de carne electrico modelo tc12n

- médias pour broyeur à boulets pour la couleur

- concassage et de criblage entrepreneur 021

- fournisseur usine de sable de silice en Nouvelle Caldonia

- broyeur à charbon vertical

- broyeur de minerai de chrome vendre

- l érection de l usine de concassage

- pour broyer le minerai de chrome

- broyeur de clinker au charbon

- les concasseurs et leurs prix

- importateurs de broyeur piedra au chili

- concasseur de pyrite en Côted’Ivoire