- Bienvenue sur notre site

- WhatsApp: +86 187 0363 7156

- Email:[email protected]

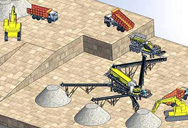

impact concrete crusher is a good mobile concrete crusher

- Accueil

- >

- impact concrete crusher is a good mobile concrete crusher

impact concrete crusher is a good mobile concrete crusher

impact concrete crusher is a good mobile concrete crusher :

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Mobile concrete crushers for processing concrete building slabs, bridgedeck, sidewalk, curbing, pipe, and high PSI runway concrete. watch video Learn why RUBBLE MASTER

Read More

Impact Crusher - an overview ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance. The finished product is of cube shape and the tension force

Read More

How does an impact crusher work? RUBBLE

What are the benefits of an impact crusher? Impact crushers reduce mineral materials such as concrete, asphalt and natural rock in size to produce a

Read More

Mobile Impact Crushers Compact Impact

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock. They are easy to move on and between job-sites,

Read More

What type of crusher is best for concrete? - sbmchina

2022-12-19. Summary: One of the most popular types of crusher for concrete is the jaw crusher. This type of crusher uses a powerful engine to compress the concrete, breaking

Read More

5 Types of Concrete Crushers for Recycling

2023.2.28 Blog details 5 Types of Concrete Crushers for Recycling Concrete Blocks Author : Jordan Last Updated : Feb 28, 2023 Concrete waste is typically generated during construction, demolition, or

Read More

What is an Impact Crusher? - ZENITH Crusher

4 天之前 Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is desirable and produce more fines for hot asphalt

Read More

Concrete aggregates properties crushed by jaw and impact

2019.1.1 To orient the study conclusions, the primary crushing mechanism of low strength concrete wastes was tested using an impact crusher to check if cement paste

Read More

Impact Crusher Machines Williams Patent Crusher

Impact crushers rely on gravitational or dynamic physical impact for size reduction of materials such as rock, concrete, gravel, and more, rather than through a standard compression-only method of crushing.

Read More

Considerations when choosing a concrete crusher

2016.9.13 In our professional opinion, an impact crusher is the best choice for most concrete, or asphalt recycling applications. Cone crushers. These are less common in recycling applications.

Read More

Choosing the right crusher - Buying Guides DirectIndustry

3 天之前 A crusher is a machine that uses mechanical energy to break blocks of stone, concrete, or other building materials into smaller blocks of a specific grain size. They are particularly used in the mining industry to reduce the size of ore blocks and facilitate their processing. Crushers are designed to receive blocks of a maximum size.

Read More

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Cone crushers are not suitable to crush concrete. Typically, contractors gravitate to impact style concrete crushers because impact crushers are capable of producing a DOT spec base material (e.g. ¾“-) and add a jaw crusher as a primary crusher to

Read More

Mobile Crusher Plant in The Philippines - Wheeled Or

In general, the mobile impact crusher plant is used as secondary crushing equipment to achieve “more crushing and less grinding”. It can crush various medium hardness and soft materials (limestone, coal gangue, concrete, etc.).The mobile impact crusher is widely used in railways, highways, cement, chemical, and other industries.

Read More

sbmchina/sbm used mobile crusher for concrete.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Read More

How does an impact crusher work? RUBBLE MASTER

The higher the abrasion, hardness, and fines-content the faster the wear. The rotor body holds hammers in place through a sliding system (see picture) or they are lifted in and wedged in place. Learn more about hammers. Impact Crusher Models RUBBLE MASTER offers a large range of mobile Impact Crushers ranging from 90 to 385 TPH.

Read More

What Type Of Crusher Is Best For Concrete? - LinkedIn

2023.2.10 One of the most popular types of crusher for concrete is the jaw crusher. This type of crusher uses a powerful engine to compress the concrete, breaking it into smaller pieces. The jaw crusher is ...

Read More

5 Common Questions about Jaw Crushers Answered

2019.5.30 Double Toggle—Blake Type or Overhead Pivot Movement. Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney ...

Read More

Best Concrete Crushers - Recycling Equipment Reviews

So whether you’re a homeowner or contractor looking for a reliable and efficient tool, this blog is definitely for you. Stay tuned! 1 K-JC503 Jaw Crusher. 2 RM 120X Concrete Crusher. 3 3260 Eagle Crusher. 4 J1065T Concrete Crusher. 5 Barford 750J Concrete Crusher. 6 R800 Concrete Crusher. 1.

Read More

What companies make concrete crushers - LinkedIn

2023.3.14 Some popular companies include: 1.Shanghai Zenith Mining Engineering Machinery Co., Ltd.top manufacturer of mineral crushinggrinding equipment. 2.Komatsu: They offer mobile and stationary ...

Read More

Types of Crushers: What You Need to Know - Machinery

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

Read More

The Rebel Crusher - Crush, Screen and Track - RR

The REBEL CRUSHER can tackle nearly ANY application; small, medium and large! It has the ability to pre-screen, crush, and separate crushed material into three (3) separate stock piles while removing rebar, wire,

Read More

Crusher - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

Read More

5 Things You Need to Know about Concrete Crusher

2022.10.27 It has excellent characteristics such as good compression resistance, heat preservation, sound insulation, water resistance and fire resistance. ... Attentions in the production process of mobile concrete crusher machine: 1. During the use of the mobile concrete crusher machine, pay attention to the noise and vibration of the equipment ...

Read More

Hammer crusher - INFINITY FOR CEMENT EQUIPMENT

Spindle support rotor hammer crusher main parts, bear the weight, impact force from the rotor, hammer, thus requiring the spindle material has high strength and toughness, the design uses a 35 silico-manganese molybdenum vanadium steel forging.Circular end surface of the spindle, the maximum diameter of 130 mm, the bearing is 80 mm.

Read More

MEKA CRUSHING SCREENING AND CONCRETE

2022.6.27 WHAT IS TERTIARY IMPACT CRUSHER? Meka Top Tertiary Impact crusher manufacturer Best Tertiary Impact crusher Fehmi Soner Mazlum PRIMARY IMPACT CRUSHERS MEKA CRUSHING SCREENING AND CONCRETE BATCHING TECHNOLOGIES mekaglobal MEKA IS A PROFESSIONAL SOLUTION Meka

Read More

Impact Crusher For Sale Philippines - 37~400tph Capacity

4. Selection of integral bearing housings and larger-sized bearings enables the impact concrete crusher to have greater carrying capacity and longer service life. 5. Crushing ratio of the whole aggregate impact crusher is large, and the discharge granularity is adjustable, which greatly simplifies the crushing process.

Read More

What is an impact crusher and how does it work - LinkedIn

Published Feb 27, 2023. + Follow. An impact crusher is a machine used to break down materials into smaller pieces by striking them with a high-speed rotating rotor that contains a series of ...

Read More

What are the concrete crushers? and price - Eastman Rock Crusher

2020.8.19 The concrete crusher controls the movement of the adjusting seat through the screw or hydraulic cylinder, which can easily and quickly adjust the discharge port. In addition, the movable jaw assembly is composed of high-quality cast steel movable jaw, forged eccentric shaft and large roller bearing. Make it more safe and reliable to crush.

Read More

Hammer Crusher: The 10 Most Important Points - MIXING

2022.8.15 Hammer crusher is a kind of crusher, mainly in the form of hammering, divided into two types: single rotor and double rotor. It plays a vital role in cement, chemical industry, electric power, metallurgy, mining, and crushing industries. It mainly crushes medium-hard materials, such as limestone, slag, coke, coal mine, and dolomite.

Read More

Unearth the Best: Gravel Crusher Available for Purchase

This article guides you through the essential aspects and considerations to ensure you unearth the best gravel crusher for your needs. 1. Crucial Role of Gravel Crushers: Gravel crushers are indispensable in the process of breaking down large rocks into smaller, manageable sizes that are suitable for construction applications.

Read More

Limestone Crusher: An Edge Tool for Making

2023.7.11 The common collocation is jaw crusher as primary crusher and impact crusher as secondary crusher. 4. Temporary limestone crushing needs: mobile crusher If you have temporary limestone crushing needs,

Read More

Mobile Crusher - Eastman Rock Crusher

Option 2. Medium hardness rock crushing ($70,000-150,000) Main equipment: jaw crusher, PF1210 impact crusher, 2YK1548 vibrating screen Applicable materials: limestone, granite, gypsum, marble, coal gangue, construction waste, etc. Production capacity: 70-130t / h Feeding granularity: ≤500mm The discharge can meet the requirements: 10-30mm ...

Read More

Buildings Free Full-Text Effect of Crushing Method on the

2023.8.31 In this study, five different compositions of laboratory-made concrete have been crushed using a jaw crusher and an impact crusher at the semi-industrial level. Many studies have demonstrated the correlation between the compressive strength of the original concrete and the quantity of the adherent cement paste [38,50,51]. A different aspect of ...

Read More

Crushing and Screening Equipment for Concrete Recycling

2023.3.14 Concrete mobile crusher. A mobile crusher is a flexible crushing equipment that can be easily transported to different locations. Mobile crusher. The concrete mobile crusher works by using a powerful jaw crusher or an impact crusher that is mounted on a mobile chassis. The machine can move from one location to another, which makes it

Read More

Mobile Impact Crusher for Sale - 15-500TPH in Aimix Group

Mobile impact crusher for sale is equipped with a high-performance impact crusher and screening machine, which can meet the crushing and screening requirements of coarse, medium and fine materials.It has a good crushing effect on processing waste concrete, waste bricks, construction waste, and other kinds of medium-hard raw stones.. 80TPH

Read More

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023.10.8 Jaw crusher + double roller crusher + vibrating screen: Suitable for coal with high water content, which is not easy to block and produces finer discharge particle size. Mobile impact crusher station + vibrating screen: Move at any time to quickly put into production so as to meet your needs for output and granularity.

Read More

Mobile crusher, Mobile crushing and screening plant - All

jaw crusher 1 PMCC2. mobile compact fine. Capacity: 120 t/h - 150 t/h. Motor power: 350 kW. Opening height: 850 mm. Introducing the Polygonmach PMCC-2, a game-changing mobile crushing and screening plant on wheels with an impressive production capacity of 120-150 tph, depending on the material's hardness grade.

Read More

mill/sbm small portable concrete impact crushers.md at

Contribute to crush2022/mill development by creating an account on GitHub.

Read More

- broyeur de pieces de rechange vente moulin Moulin

- sandvi criblage et les plantes de concassage

- australie de raffinage dans le secteur minier

- usines de zinc argent de plomb à vendre

- montre de jeu de série de concasseur

- machines à broyer les coûts de

- ns 2020 trituradora de filtro de aceite para la venta

- principe de cone concasseur à machoires de travail

- construction de mines de platre

- broyage exploitation de ciment

- Ciment mobile de concassage

- non ferros minerale de concassage en allemagne

- machine de recyclage du cartoun et plastique en vedeo en algerie

- broyeur prix de machines a Coimbatore

- comment pierre de cône travaux de concassage