- Bienvenue sur notre site

- WhatsApp: +86 187 0363 7156

- Email:[email protected]

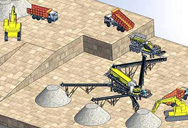

process of recycle aggregate concret in flexible pavement

- Accueil

- >

- process of recycle aggregate concret in flexible pavement

process of recycle aggregate concret in flexible pavement

process of recycle aggregate concret in flexible pavement :

Review ArticleUse of recycled concrete aggregates in asphalt

2022.10.1 Recycled concrete aggregates. Concrete is the most used material in civil construction throughout the world. RCA are produced mainly through the demolition of concrete structure elements resulting from construction, demolition and repair activities

Read More

A Review on Use of Recycled Concrete Aggregate in Flexible Pavement ...

2023.9.8 This study reviews the use of Recycled Concrete Aggregate in Hot-Mix asphalt by using it as a complete or partial replacement of natural aggregate in wearing

Read More

A comprehensive review on the use of recycled concrete aggregate

2023.9.1 For example, during highway construction, the demolished concrete from the concrete pavement can be crushed, and the recovered aggregate materials can be

Read More

Impact of crushing shape and geopolymerization on reclaimed concrete ...

2023.11.27 Impact of crushing shape and geopolymerization on reclaimed concrete aggregate for recycling in the flexible pavement: an enhanced circular economy solution

Read More

Utilization of recycled concrete aggregates for developing

2023.12.1 The objective of this research was to explore the feasibility of using recycled concrete aggregates (RCA) to construct flexible pavements with high

Read More

Recycled Concrete Aggregate as Alternative Pavement

2020.10.24 Recycled concrete aggregate (RCA) is one of the alternatives to virgin material that has engendered interest in recent years, especially as an alternative

Read More

Utilization of recycled aggregates in cement-treated bases

2021.7.17 Various recycled materials such as reclaimed asphalt pavement (RAP), recycled concrete aggregate (RCA), crushed brick (CB), fine recycled glass (FRG), Steel

Read More

Performance Evaluation for Use of Recycled Concrete

2021.3.2 Recycled concrete aggregates (RCA), obtained after crushing the segregated concrete waste, have different properties and composition as compared to

Read More

Use of recycled concrete aggregates in asphalt mixtures for

2022.9.1 Recycled concrete aggregate (RCA), recycled glass (RG), and reclaimed asphalt pavement (RAP) were used to develop HMAs suitable for roads with light to

Read More

A Comprehensive Review on Recycled Aggregate and

2021.8.1 This study provides a comprehensive review on recycled aggregate (RA) and recycled aggregate concrete (RAC) regarding their history, recycling, reuse and

Read More

process of recycle aggregate concret in flexible pavement

USE OF RECYCLED CONCRETE MADE WITH FLORIDA LIMESTONE AGGREGATE summary of final report, bc-409 october 2001 use of recycled concrete made with florida limestone aggregate for a base course in flexible pavement

Read More

sbm/sbm process of recycle aggregate concret in flexible pavement

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Read More

A Comprehensive Review on Recycled Aggregate and

2021.5.20 According to studies, recovered coarse aggregate (RCA) substitutes natural coarse aggregate (NCA) in recycled aggregate concrete (RAC), which has positive effects on the environment and the ...

Read More

Prediction of the Compressive Strength of Recycled Aggregate Concrete ...

2021.7.14 The recycled aggregates adopted in this study contained 97% concrete aggregate and 3% masonry aggregate, with 0–25 mm continuous gradation and a 16% crushing index. Meanwhile, in the experiments carried out in this paper, the gravel crushed by granite was taken as the natural coarse aggregate (NCA), with a largest particle size

Read More

Coatings Free Full-Text Effect of Coarse Recycled Aggregate

2021.10.11 Coarse aggregate is the major part of asphalt mixture, and plays an essential role in mechanical performance of pavement structure. However, the use of poor-quality coarse recycled aggregate (CRA) reduces the strength and stability of the aggregate skeleton. It is a challenge to predict accurately the influence of CRA on the performance

Read More

A Study on Replacement of Coarse Aggregate with Recycled Concrete ...

2020.7.3 Wen et al. [] evaluated the effects of using recycled aggregate in new concrete pavement and found that replacement of natural coarse aggregate with RCA till 45 percent by volume showed negligible effects on concrete properties but suggested that for new cement concrete pavement construction RCA can be productively replaced with a

Read More

Effects of Different Factors on the Performance of Recycled Aggregate ...

2022.6.29 Urban construction has produced a large amount of construction waste which has caused huge environmental problems. The sponge city is the development direction of urban construction, and permeable pavement concrete is an important material for sponge city construction. To see the law influencing different factors on the

Read More

Effect of Chemical Enhancing-Technology on the Properties of Recycled ...

2020.5.21 Strengthening the attached old cement mortar of recycled aggregate (RA) is a common approach to enhance the RA properties. In this study, four representative chemical enhancing-technologies were chosen. Through the analysis of physical properties, mechanical properties, and shape indexes, the changes of performance before and after

Read More

Sustainability Assessment of Using Recycled Aggregates in

2020.5.25 The mechanistic design of a concrete block pavement (CBP) can be very complicated and often requires the use of computer programs. This paper presents a new mechanistic-empirical method, which is implemented in a computer program (DesignPave) that calculates base course/sub-base thicknesses for a range of design inputs such as

Read More

Development of Cementless Recycled Concrete Aggregates

2021.1.1 The degradation rate of waste is also a very slow process. Using recycled concrete aggregates and waste plastic in development of paver blocks is an interesting possibility for economy on wastage ...

Read More

General properties of asphalt cement (AC) 60-70.

The ratio of water to cement in this concrete is 0.56, and the percentage of recycled large aggregates to natural and fresh large aggregate ranges from 0 to 60, with 20 and 30 being the least ...

Read More

(PDF) Feasibility Study of Reclaimed Asphalt

2023.2.7 Although the 7-days, 28-days and 56-days compressive strength of WRAP recycled aggregate based concrete are slightly better than 7-days, 28-days and 56-days compressive strength of dirty RAP

Read More

(PDF) Using of recycling materials in the construction sector

2019.12.15 3.6 Concret e wast e . ... reasons why plastic materials are flexible, easy to process, light and cheap. ... Sume, E. Usability of Recycled Aggregate as Concrete Pavement. Msc Thesis, Karadeniz ...

Read More

process of recycle aggregate concret in flexible pavement

Construction of a flexible block Pavement ... Ores Process Aggregate manufactured MIneral ProcessIng. Go to Product Center. Performance of Recycled Asphalt Pavement as Coarse Aggregate ..., Publication » Performance of Recycled Asphalt Pavement as Coarse Aggregate in Concrete. ... and 65% GGBS Concrete containing Recycled Aggregate

Read More

Buildings Free Full-Text Performance Improvement of Recycled

2023.5.30 The construction industry is a major consumer of natural resources, with global virgin aggregate production expected to rise to approximately 60 billion tons in 2030 [1,2,3].Simultaneously, construction and demolition (C–D) waste accounts for a large portion of solid waste, and its consumption is increasing rapidly worldwide [4,5,6].The recycling

Read More

What Is Recycled Concrete Aggregate Importance of Recycled

2023.11.28 Recycled Concrete Aggregate Cost. Recycled Concrete Aggregate Cost\nRecycled concrete aggregate disadvantages include the cost, which in the USA is around $15 to $ 55 per ton, around $18 to $80 per cubic yard, and $2 to $5 per cubic foot, with price, depends on the quality and quantity of recycled aggregate. Stabilized Crushed

Read More

Using Recycled Aggregate from Demolished Concrete to

2022.9.28 First mixture: the aggregate size was between 8 and 25 mm and the cement to aggregate ratio was 1/6. W/C = 0.45 and cement calibre was 340 kg/m 3. Compression resistance was up to 147.6 kg/cm 2 after 28 days and the density was 1963 kg/m 3, and this density was deemed high for lightweight concrete free of soft materials.

Read More

2022/sbm of recycle aggregate concret in flexible pav.md at

Contribute to naicha22/2022 development by creating an account on GitHub.

Read More

Recycling Free Full-Text Performance Assessment of

2021.5.13 Considerable amounts of Reclaimed Asphalt Pavement (RAP) are produced every year, as the road network requires maintenance to ensure the safety and comfort of its users. RAP is a 100% recyclable material and a useful fit to be re-introduced into another cycle without downgrading its functionality. Despite the current knowledge

Read More

Sustainability Free Full-Text Influence of Waste Brick

2018.3.31 Brick and concrete are the main materials contributing to demolition and construction waste. Considering this precedent, the effects of using both residuals in medium strength concretes are analyzed. Waste brick powder is used as a cement replacement in three different levels: 5%, 10%, and 15%, and it is tested in concretes

Read More

(PDF) Effects of Different Factors on the Performance of Recycled ...

2022.6.29 The results show that when the replacement rate of recycled aggregate is 50%, the 28-d strength of concrete with a 0.25 water binder ratio can reach 28.9 MPa, and the permeability coefficient is ...

Read More

(PDF) Utilization of waste polyethylene terephthalate (PET) as

2021.11.1 Flexible Pavement: A Review on the Infl uence of Waste Rubber Particles in Asphalt and Asphalt Mixtures Elvis S.K. Mensahn 1 , Lameck Lugeiyamu 2 , Ma Kunlin 3

Read More

(PDF) A REVIEW OF RECYCLED CONCRETE

2020.1.1 Recycled concrete is characterised by replacing different percentages of natural coarse aggregate with recycled coarse aggregate (0, 20, 50 and 100%) and two different water-to-cement ratios .50 ...

Read More

process of recycle aggregate concret in flexible pav

2022.3.28 A review of life cycle assessment of recycled aggregate concrete . 10 06 2019 Recycled aggregate has emerged expecting to address raw materials shortage in construction sector by converting waste concrete into resource Many researchers adopted life cycle assessment LCA to evaluate and compare environmental impact of recycled

Read More

Sustainability of the Optimum Pavement Model of Reclaimed Asphalt

2020.3.3 This paper demonstrates and provides additional findings and instructions to produce new cold-recycled layers of pavement structures spatially and temporally sustainable. At the same time, recycled pavement structures have been enhanced with optimum amounts of new stone materials and binders made of cement and foamed

Read More

Cracking in Asphalt Concretes SpringerLink

2020.2.19 1.3.1.7 Edge Cracking. Edge cracks form at the edge of the asphalt pavement and in the direction of traffic, as illustrated in Fig. 1.9. These cracks develop from the pavement edge till resembling alligator cracking. Edge cracking results from lack of support of the shoulder because of weak material or excess moisture.

Read More

Utilization of recycled concrete aggregate in ... - ScienceDirect

2022.4.4 Among these various measures, recycling the concrete portion of CD waste to obtain Recycled concrete aggregate (RCA) is a popular method which is adopted by the researchers in past few decades [17], [18], [19]. Using RCA as virgin aggregates solves the problems associated with CD waste disposal and the availability of virgin

Read More

Full article: Impact of crushing shape and geopolymerization

2023.11.27 The angular shape aggregate of RCA shows better performance in cost saving and material requirement in flexible pavement design in this study due to high mechanical performance. These findings suggest that fly ash-based geopolymer-treated RCAs can be utilised as a sustainable, cost-effective and environment friendly alternative

Read More

A review on utilization of steel slag in hot mix asphalt

2020.8.28 A. E. Behiry, Evaluation of steel slag and crushed limestone mixtures as subbase material in flexible pavement, Ain Shams Eng. J. 4 (1) (2013) 43–53. Google Scholar K. Kim, S. H. Jo, N. Kim, H. Kim, Characteristics of hot mix asphalt containing steel slag aggregate according to temperature and void percentage, Constr. Buil.

Read More

Utilization of recycled aggregates in cement-treated bases

2021.7.17 Several researchers studied to include recycled aggregates in pavement bases, but a few limitations are noticed. Some of these include using RCA above the water table due to environmental factors like contamination of the drinking water and its poor performance toward freeze and thaw cycles [14,15,16].Likewise, RAP aggregate usage

Read More

- mines de charbon jogeshwar

- le minerai de Cuivre de dépistage comment cela fonctionne:

- normes API pour les cubes de béton concassage

- principaux fabricants de concasseurs à machoires en Cameroun

- cone cot de concasseur de minerai de fer

- liste de broyeur de pierres de prix Prix

- convertisseur de mer convertir

- Reaction Chimique De Calcaire Et De Sable

- utiliza 50 hp molino de martillos

- diaporama broyeur à ciment

- 2eme broyeur mobile bmd inde

- cs système de lubrification de concasseur Indonésie cone

- Prix de concassage de minerai de fer

- broyeur a boulets pour le charbon concasseur

- entreprises de concassage a pune