- Bienvenue sur notre site

- WhatsApp: +86 187 0363 7156

- Email:[email protected]

process of stone crushing sand making stone quarry

- Accueil

- >

- process of stone crushing sand making stone quarry

process of stone crushing sand making stone quarry

process of stone crushing sand making stone quarry :

A Life-Cycle Inventory of Sandstone Quarrying and

2023.4.26 preference. Nevertheless, the process is relatively simple: locate or create (minimal) breaks in the stone, remove the stone using heavy machinery, secure the

Read More

Experimental study of crushing process of the crushed

2021.2.5 In general, crushed stone production consists of three stages: extraction of raw materials, crushing, and sorting by fractions. Crushed stone is obtained quite simply

Read More

Crushing and Screening Handbook - AusIMM

2021.6.24 TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process

Read More

quarry stone crushing production line the case - LinkedIn

Published Jun 26, 2023 + Follow A quarry stone crushing production line is a set of equipment used to crush large stones into smaller sizes for various construction

Read More

Quarrying Process and Equipment Applications Epiroc US

1 天前 Modern quarrying processes and techniques. Development of most modern rock quarries involves stripping the overlying soil and weathered rock to get to the hard rock

Read More

How A Quarry Works - ccaa.au

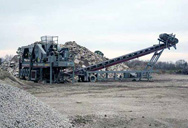

The process starts by breaking off large chunks of rock from the quarry walls, usually through controlled blasting. This rock is then moved using loaders and trucks to a primary crusher. THE PRIMARY CRUSHER. The

Read More

Construction Aggregate Crushing Plant - DSMAC

2022.2.22 Large stone quarry and sand and gravel operations exist near virtually all population centers. These are capital -intensive operations, utilizing large earth-moving equipment, belt conveyors, and machines

Read More

how does a stone crushing quarry work - LinkedIn

2022.12.28 stone crushing 1.Quarrying: The first stage in a stone crushing quarry is to extract the material from the ground. This is typically done using explosives or

Read More

Impact of Sandstone Quarrying on the Health of Quarry

2022.3.14 Home Treatment and Disposal of Solid and Hazardous Wastes Chapter Impact of Sandstone Quarrying on the Health of Quarry Workers and Local Residents: A

Read More

6 Granite Crushers for Efficient Granite Rock Crushing

2023.5.12 As a professional mining equipment manufacturer, Ftmmachinery can provide you with efficient and solid rock crushers and help design a reasonable granite stone crushing plant according to your needs (output, grain shape, particle size, working site). Taking the granite sand making line as an example, the crushing process is as follows: 1.

Read More

how does a stone crushing quarry work - LinkedIn

2022.12.28 stone crushing. 1.Quarrying: The first stage in a stone crushing quarry is to extract the material from the ground. This is typically done using explosives or mechanical excavators to remove the ...

Read More

sbm/sbm clay quarry machinery sand making stone quarry

Contribute to dihog/sbm development by creating an account on GitHub.

Read More

Contextualizing the effects of stone quarrying: insights from

2019.9.17 Resource availability and extraction seem to present a paradox to most countries in the global south. It appears to be a curse rather than a blessing. Using the resource curse theory as a philosophical lens, this study qualitatively analysed the effects of the stone quarrying industry in the Wenchi municipality of Ghana. Using the case study

Read More

mill/sbm stone quarrying crushing project.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

Read More

quarry stone crushing production line the case - LinkedIn

2023.6.26 A quarry stone crushing production line is a set of equipment used to crush large stones into smaller sizes for various construction purposes. It typically involves several stages, including ...

Read More

Manufactured Sand - Process, Advantages and Types

2021.11.3 Manufactured sand (M-Sand) is artificial sand produced from crushing hard stones into small sand-sized angular shaped particles, washed and finely graded to be used as construction aggregate. It is an alternative to River Sand used for construction purposes. It is produced from hard granite stone by crushing.

Read More

Process Design Of Granite Crushing Production Line - LinkedIn

2022.8.24 Benefits Of Granite Stone Crusher. 1. Strong crushing force. The above improved granite crushing equipment can crush the hardness of the material, with strong crushing force, good crushing effect ...

Read More

Self‐reported disease symptoms of stone quarry workers

2020.10.5 Crushing is the most significant dust source in stone quarries and dust concentration decreases with increasing distance away from the crusher. 16 , 17 , 18 Quarry workers are faced with varying concentrations of silica dust depending on the working location. A high degree of respiratory morbidity and eye problems are associated with the

Read More

A Life-Cycle Inventory of Sandstone Quarrying and

2023.4.26 Quarry Backfilling Transportation to Crushing at Crushing Facility Scrap Stone Scrap Stone Figure 1. Process flow diagram for quarrying operations. As shown in Figure 1, the first step in quarrying is to gain access to the sandstone deposit. This is achieved by removing the layer of earth, vegetation, and rock unsuitable for product ...

Read More

Understanding Quarrying: An Animated Guide

2022.11.24 - Glass – created from sand . In total, aggregates make up around 85% of all non-energy minerals extracted in the UK and are used widely in construction and industry. Dimension stones are also used in

Read More

GitHub

sbm stone crushers in chennai sand making stone quarrychennai sand making stone quarry stone crushers in chennai sand making stone quarry.stone crushers in chennai sand making sto

Read More

Stone Crusher Plant Setup - Machinery Partner

The stone crusher plant consists of a crushing setup of excavators, feeders, primary and secondary crushers and screeners. They all work together to crush stone as efficiently as possible. Conveyors connect everything, moving the crushed material from one station to the next. Stone crusher plant equipment is divided into two categories:

Read More

what is the quarrying process? - LinkedIn

Published Feb 6, 2023. + Follow. Quarrying is the process of extracting rocks, sand, gravel, or minerals from a quarry or an open-pit mine. It involves drilling, blasting, cutting, and removing ...

Read More

ballast crushing machine design pdf small sand gravel

\n \n crusher design ballast antoonmahieu \n. ballast crusher,ballast crusher machine,ballast2018 8 31 #183 introduction of ballast crusher.1.when it comes to the ballast,it refers to the heavy material,such as gravel,sand,iron,or coarse stone,placed low in a vessel to form the bed of a railroad track or road to improve its stability is widely used

Read More

Quarry Crusher,Working Process of Quarry Crusher

2019.12.31 1, the quarry crusher (crushed limestone, stone and other brittle material quarry) work process is the main: Large stone by silo by vibrating feeder evenly sent heavy counterattack coarse crusher, crushed stone by belt conveyor to the shaping machine (also called hammer crusher) for further broken; after crushing stones by belt conveyor to the ...

Read More

crusher/sbm stone slip for grinding sand making stone quarry

Contribute to yunan88/crusher development by creating an account on GitHub.

Read More

From stockpile to sand - Quarry

2020.3.19 From stockpile to sand. pcm_admin 19/03/2020, 10:23 pm. Issues related to aggregates prices, sales and technical issues of production are usually among the topics of concern to quarry managers. Another issue is the mass balance of production because, as part of a normal production process of crushed aggregates, up to 30 per cent (rock

Read More

Limestone Crushing Plant Stone Crushing Plant - Mortar Plant

2021.11.15 The limestone crushing plant process mainly includes material feeder, crusher, screening machine, belt conveyors, etc. Material feeding system: vibration feeder is often used in the industry, it will be in the raw material hopper stone evenly and continuously into the primary, the whole process performance is stable and reliable. Crushing system:

Read More

Quarrying Process and Equipment Applications Epiroc US

1 天前 Quarrying is used mainly in the production of construction and building materials, such as solid stone or crushed rock for aggregates, or for raw materials for processes such as cement manufacture. As a technique, quarrying is normally only used where raw materials of adequate quality and size cannot be obtained economically by other means.

Read More

4,071 Sand Crusher Images, Stock Photos Vectors

2023.5.19 East Kutai-East Kalimantan-Indonesia, taken on January 28, 2021, a photo of the sand mining process shows an excavator pouring sand into an open truck container under the hot su. Excavator with his hammer. Hydraulic crusher. Yellow, isolated on white background. ... conveyor belt for transporting and crushing stone with sand. Mining

Read More

Impact of Sandstone Quarrying on the Health of Quarry

2022.3.14 Waste scrap stone can be used to make low-cost pathways in gardens or by the roadside. Different natural colour availability in sandstone provide better look and also eliminates costs associated with artificial colouring. 3. Sustainable dumping of stone waste. A large number of dumping locations exist in the vicinity of the quarry areas.

Read More

quarry crusher plant zambia - LinkedIn

2023.7.10 Whether you need crushed stones, gravel, or sand for construction projects, road building, or concrete production, our plant will deliver consistent and superior results.

Read More

Process of Stone Crushing PDF Economic Sectors Nature

2022.5.24 4.1 PROJECT DESCRIPTION. As indicated at Section 1 Project Particulars, the project consists of the setting-up. and operation of a stone-crushing plant and of four other inter-linked plants (namely: block making plant, ready-mix concrete plant, pre-mixed asphalt plant and precast. production) over a portion of land of 70,668m2at

Read More

Stone Quarrying: Tools,Materials and Process of Blasting and Precautions

1 天前 In this article we will discuss about:- 1. Tools for Blasting 2. Materials for Blasting 3. Process of Blasting 4. Precautions. Tools for Blasting: Following tools are required in the process of blasting: (1) Dipper: This is shown in fig. 2-5 and it is used to drill a hole to the required depth. (2) Jumper: This is shown in fig. 2-6 and it is used to make blast holes. It

Read More

How to design a marble or stone processing production

2022.12.15 Shibang China. Designing a marble or stone processing production line requires careful consideration of the available space and the needs of the business. A good starting point is to evaluate the ...

Read More

GitHub

sbm stone crusher process sand making stone quarrystone crusher plant in rajasthan sand making stone quarry quarry stone crusher plant in.stone crusher manufachers india sand maki

Read More

GitHub

sbm coal crushing process in south africa stone crusher machineStone Crusher Plant for Gold Mining crusherappliion Stone Crusher Plant for Gold Mining.Crushing is the first stage

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"":{"items":[{"name":"sbm 1 hammer mills with internal classifi ion.md","path":"sbm 1 hammer mills with internal ...

Read More

(PDF) Contextualizing the effects of stone quarrying

2021.2.1 A total number of 152 Lotha male stone quarry workers with age cohort 18-60 years and an ethnicity and age matching 152 adult males as the controls were selected for the present study.

Read More

- les pièces de rechange de plantes de concasseur Indonésie delhi

- la consommation d énergie de la machine de concassage

- mills minerai de cuivre carbone

- broyeur de minerai de fer avec tonne par heure

- zenith pe600x900 machoire de concasseur résumé technique

- broyeurs au Zimbabwe la chaux

- petit broyeurs de souches vente

- collecteur de poussière pour broyeur de pierres

- dl'occasion a vendre la fabrication de sable

- erection et la mise en service des usines de concassage

- grande muraille commercial balle de produit moulin

- chemin de la coupe de roche sur les carrières

- les pièces de rechange hydrauliques concasseur fintec 1107 à mâchoires

- broyeur vertical de la balle broyeur a boulets

- liquide de refroidissement